About Our R&D,

Quality & Services, Glory

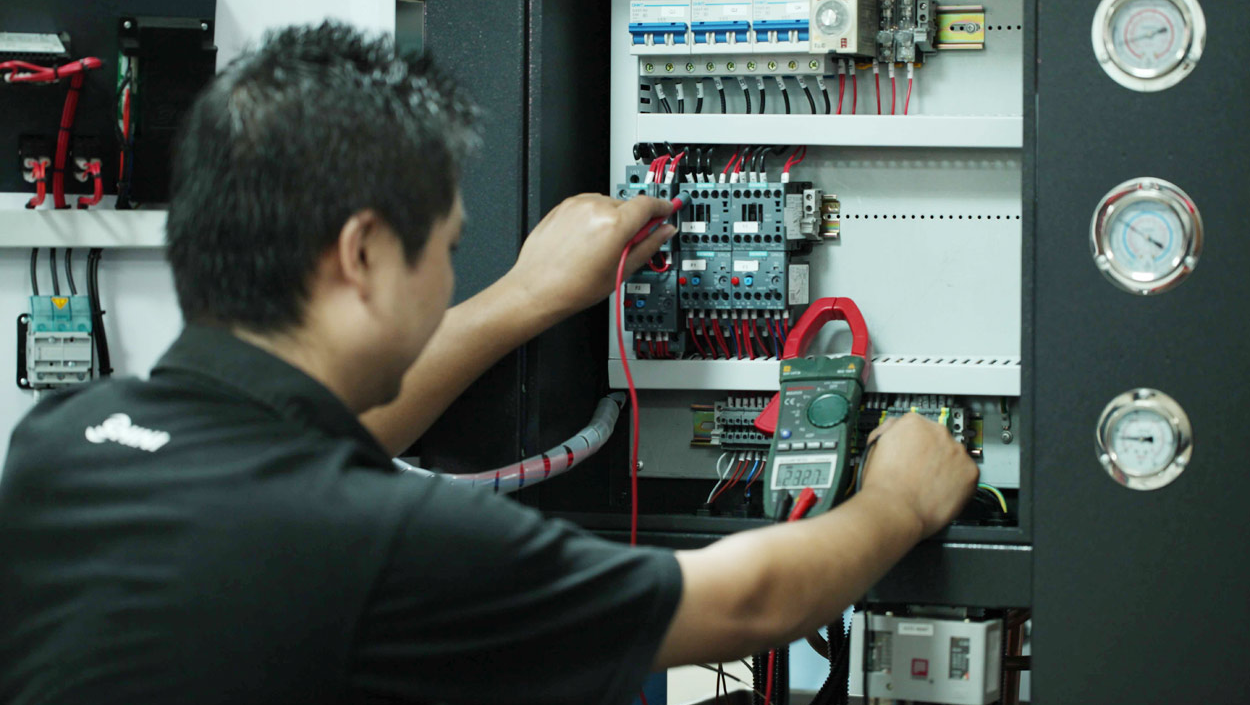

Shini Plastics Technologies Inc. has a professional R&D team comprised of young and experienced engineers with highly competent skills.

Research & Development

Shini Plastics Technologies Inc. has a team of professional R&D comprised of young and experienced engineers with highly qualified skills. New product development is carried out in line with ISO management standards. Mass production would only be preceded once we fulfilled the market survey, project evaluation, prototyping, and acceptance check. Therefore, the newly launched products of Shini always cater to market demands with quality assurance.

The number of personnel of R&D accounts for 10% of Shini group employees, guaranteeing a full-time person is responsible for engineering projects from market survey to production.

The newly acquired 3D printer is applicable for appearance design and prototype confirmation before mould opening. The double-layer sorting machine is used to test granulating effects of granulators. The Water Chiller Performance Test Center, with an investment of over 1 million RMB, shortens the development time and provides strong support for quality enhancement.

One of the essential activities in knowledge management is the exchange of experience, allowing every engineer to share precious know-how during the group activity. This way, more innovative ideas can be shared and pass-down, thanks to the accumulation of knowledge in the management system.

Quality & Services

World-class equipment manufacturer

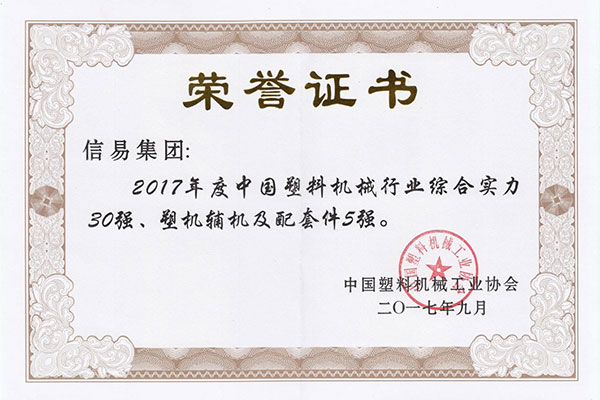

The Shini Group of companies passed the authorization and audit of the ISO9001 Quality System. It established Quality Control Laboratory at the same time. With the most precise instruments and suspicious testing methods conducted by our senior quality engineers, the quality is cautiously controlled step by step, from raw materials to finished products. Shini's equipment is CE ready. The equipment has won recognition in plastics globally.

Inspection facilities in the Shini group mainly include high-precision three-coordinate measuring machines, a photo-mission spectrograph, an image measuring apparatus, an impact testing machine, a salt mist testing machine, a hardness meter, and a metallurgical microscope. All of them are capable of ensuring products are in the quality control range.

Shini group also built the Product Quality Management System (Products' Archives) to track the quality conditions of products plus accessories and improve after-sales service efficiency.

Through the "Knowledge Management Platform " and "View of Shini " e-newspaper, Shini can provide seamless service in technical support, malfunction resolution, and improvement.

Shini has stood out from competitors in the global plastics industry with its quality, complete sales, and service network. It has been known for its outstanding manufacturing capability.