部品

-

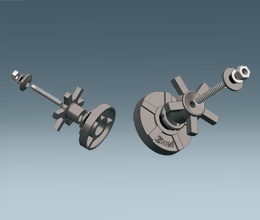

Flat mold clip

Make the work piece stable and not do any subtle movement.その他... -

Foot shock

It adopts the new installation technology which breaks the traditional installation method and allows to be put into production with installation of shock foot. Therefore, it greatly reduces the installation period, particularly conducive to integration and adjustment of the production line.その他... -

Central Control Station

SCCS series German made SIEMENS PLC controller with best design and powerful functions, it can efficiently control the system of dust cleaning, material conveying, alarming etc. The system has strong compatibility, which can support up to maximum 36 moulding machines. Easy maintenance and highly reliable so to reduce the maintenance cost. Comply with "CE" standard to ensure safe operation. Easy to operate with humanized operation interface.その他... -

Central Safety Filters

SCSF series central safety filter in central loading system adopts large dust collector to filter dust and small impurities in material so can effectively protect blower and prolong its service life. Self-cleaning function realize the effective cleaning of the filter by set-up auto timer, which can reduce manual clean times. Equipped with vacuum breaking valve to not only protect the blower, but also accelerate conveying and loading speed. その他... -

Central Vacuum Generators

In central conveying system, central vacuum generator will provide vacuum (negative pressure) power. This machine adopts high pressure blower or Roots blower as its core power, which has features like heavy-duty, great power and long service life etc to ensure continuously loading. Besides, this series offer more than 11 models with maximum 15 HP applicable to different system applications. The start of the blower is controlled via central control station and can work with equipments like Euro vacuum central hopper and central filter to realize automatic material loading function. その他... -

Material Distribution Station

The function of material distribution station is to distribute materials to corresponding storage hoppers. There are five models of SMDS series, each equipped with quick couplers, so the loading and unloading of material are convenient. The stainless steel is adopted for bulid of the station to eliminate material contamination. その他... -

sLink Protocol Solution

The system possesses control function of both injection molding machine and auxiliary equipment. Integrate the monitor functions of auxiliary equipment,like dehumidifying dryer,gravimetric blender, water chiller and mold temperature controller etc. into the control system of the injection molding machine, which realize to monitor the working state of the injection molding machine and each auxiliary equipment via the touch screen on the injection molding machine. Therefore, it can improve operation efficiency and device maintenance.その他...