Special Reports

2025 Quarter 1 Issue 53

The Application of Heatless Air Dryer

What is heatless dehumidifying drying?

Heatless dehumidifying drying utilizes the pressure swing adsorption principle to absorb moisture from the air through desiccants (such as silica gel, molecular sieves, etc.) to achieve air drying purposes.

Its major structure is hoppers A and B, which work alternatively. When the air enters hopper A, the desiccant inside the hopper (such as silica gel or molecular sieve) can absorb the moisture from the air, making the air dryer. As time passes, the desiccant will be gradually saturated. When the hopper A is saturated, the hopper B starts to work. By exhausting some dry air, hopper A can remove the absorbed moisture to finish regeneration. The drying and regenerating processes alternate between hopper A and hopper B to ensure a continuous supply of dry air.

The Application of Heatless Air Dryer Used in Plastics Industry

Plastic particles must be predried before processing to eliminate moisture and ensure a smooth process and stable product quality. For its high-efficiency and energy-saving properties, the Heatless Air Dryer has been widely used in this field, and it can work with different drying equipment to achieve the perfect drying effect on plastics.

Application Advantages of the Heatless Air Dryer

1. High efficient drying

The heatless air dryer continuously provides stable low dew-point (-40℃) dry air, ensuring that plastic particles can be thoroughly dried without moisture before processing to improve processing efficiency.

2. Low power consumption

Compared with other dryer models, the regeneration of a heatless air dryer does not require an external heating source, so it consumes little power and saves energy.

3. Easy maintenance

Because of the simple regeneration process, the maintenance cost of the heatless air dryer is relatively low, and it doesn't need complex maintenance procedures.

Typical Cases

In the drying of plastic particles, the use of heatless air dryers is very extensive, and the following are several typical cases:

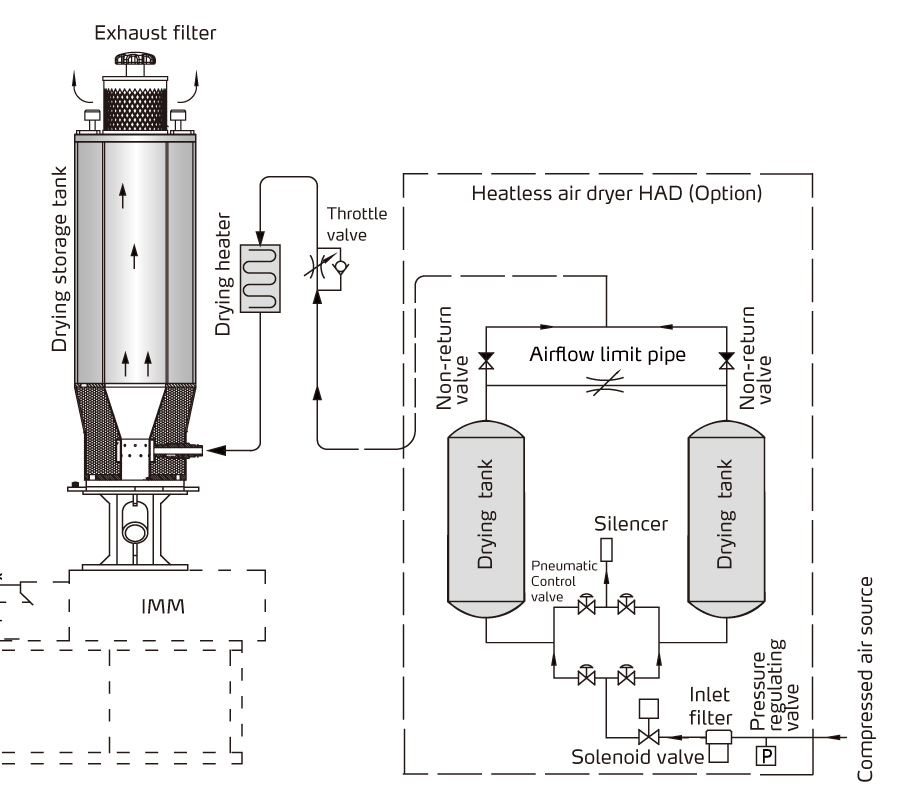

1. Working with the Compressed Air Dryer SCAD-U

This type of combination adopts an open drying loop mainly used for dehumidifying and drying small batches of materials. The Heatless Air Dryer HAD provides dry air for the Compressed Air Dryer SCAD-U, which heats the dry air to the required value and ensures that the dry air blows through the particles, thus achieving highly efficient drying.

SCAD-U Working Principle

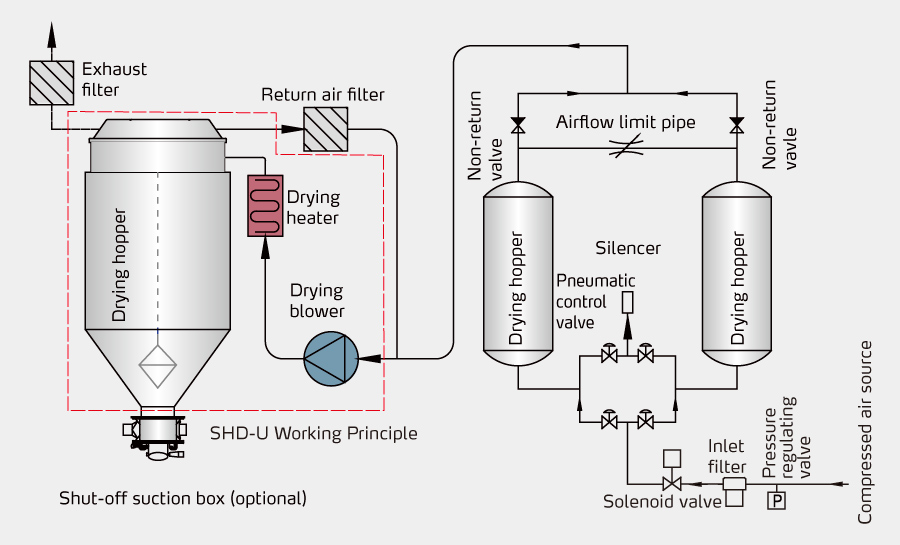

2. Working with the Hopper Dryer SHD-U

This type of combination adopts a closed drying loop, which can be used for dehumidifying and drying large batches of materials. The Heatless Air Dryer HAD provides dry air for the Hopper Dryer SHD-U, which heats up the dry air to the required value and ensures that the dry air blows through the particles, thus achieving highly efficient drying.

SHD-U-HD Working Principle

3. Used in Other Fields

The Heatless Air Dryer HAD can also be applied infields with specific air dryness requirements, such as laboratories.

Applying a heatless air dryer to dry plastic granules improves processing efficiency and product quality and has energy conservation and environmental protection advantages. As the plastics industry's drying technology requirements increase, the Heatless Air Dryer will have even broader prospects. With continuous technological innovation and progress, we will further enhance its performance to bring more benefits to the plastics industry.

Special Reports

- Energy-saving Intelligent Drying Control System

- Chinaplas2024 rounded off successfully

- NPE 2024 has ended successfully. See you again in 2027

- The AMI Plastics World Expos

If you want to read other articles, back to2025 Quarter 1 Issue 53.