Special Reports

2023 Quarter 3 Issue 51

The Role of Suction Box Plays in the Feeding System

Brief Introduction

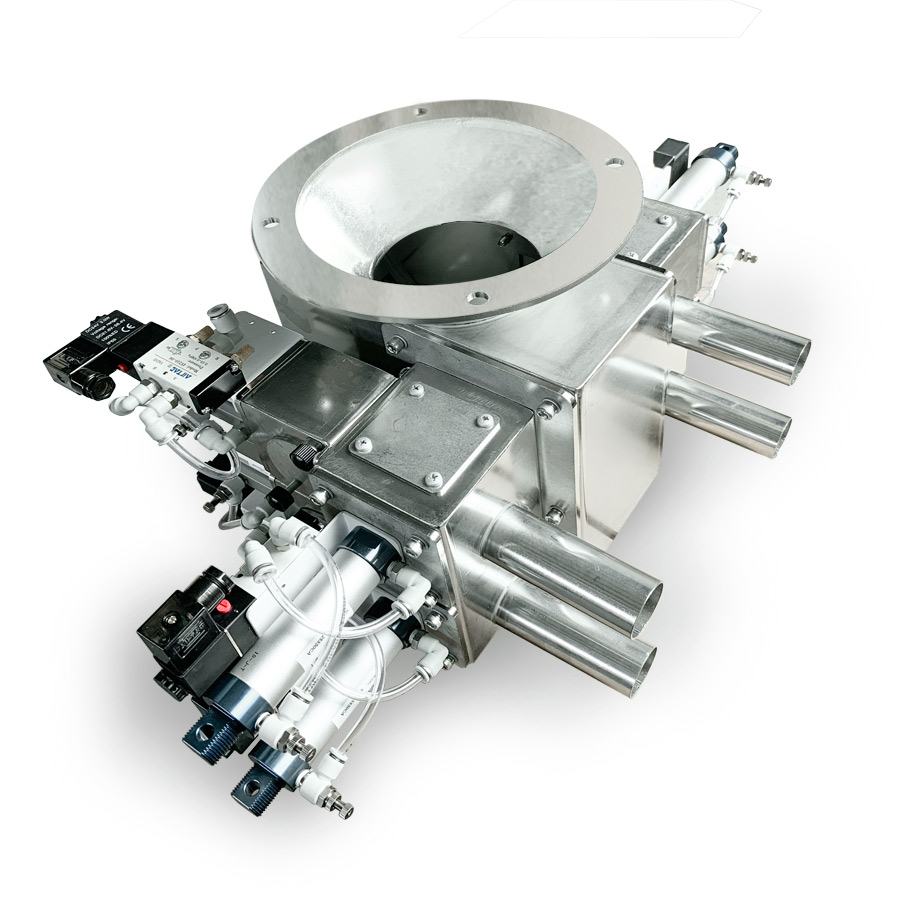

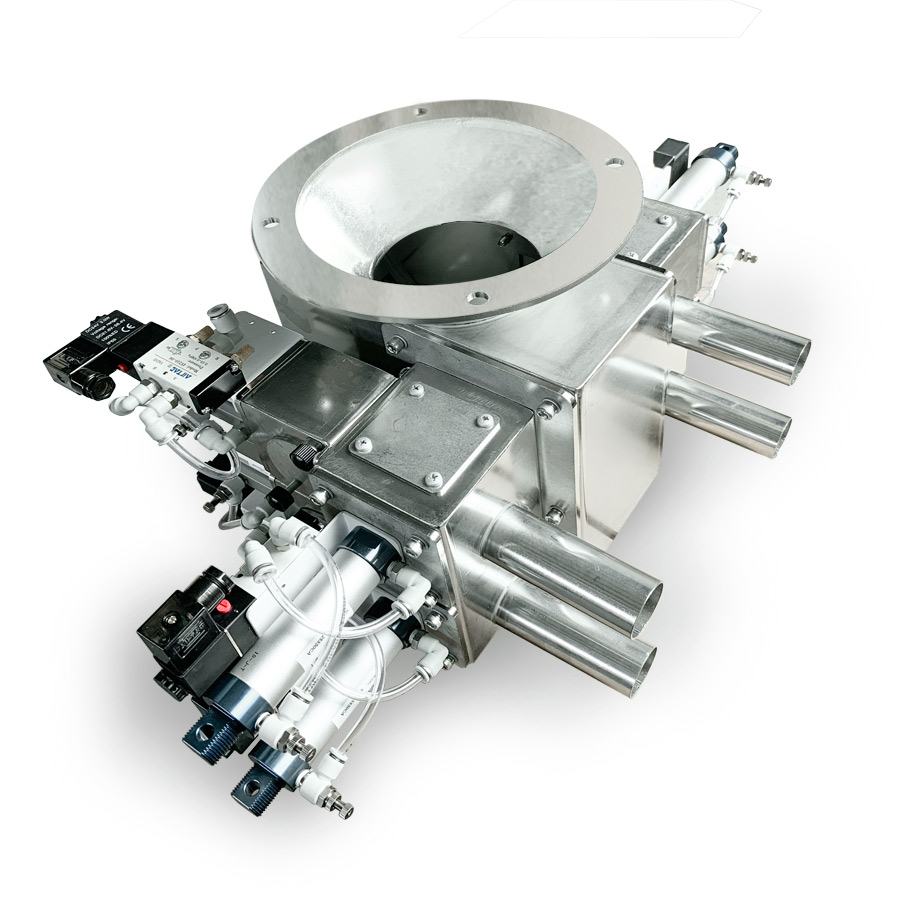

Suction box is a device installed at the material hopper or dryer bottom that used to convey plastic particles in material conveying system. It features simple structure and stable operation and plays an important role in the conveying system. Though the suction box is small, it has a significant impact for reliable conveying of the plastic particles.

Classification

In current industry, common suction boxes are classified into conventional suction boxes and shut-off suction boxes. The conventional suction box has a compact structure, simple and practical, which is suitable for short distance transportation occasions. It mainly consists of the collection section, suction section, and the discharge section.

Compared to the common suction box, the shut-off suction box has an additional shut-off section. With shut-off function, it can clean up residual materials in the pipeline that can reduce material wastes and make it convenient for manual cleaning. Even for material replacing and conveying, it also can avoid quality problems such as material mixed due to poor cleaning, which mainly consists of the collection section, shut-off section, suction section, and the discharge section. When the suction part and collection part is collected, the materials in the collection part can be transported with the suction blower. Otherwise, it’s impossible to transport.

Selection

Usually, we will select the suction box based on actual demands. If it is a relative far distance, we will select the shut-off suction box; If there’re several injection moulding machines, it can select the multiple-pipe suction box to transport materials to two or more feed ports of the IMMs. In the food, medical, or optical occasions, it can customize the materials of the suction box contacted surface or meet other requirements.

Suction box is a device installed at the material hopper or dryer bottom that used to convey plastic particles in material conveying system. It features simple structure and stable operation and plays an important role in the conveying system. Though the suction box is small, it has a significant impact for reliable conveying of the plastic particles.

Classification

In current industry, common suction boxes are classified into conventional suction boxes and shut-off suction boxes. The conventional suction box has a compact structure, simple and practical, which is suitable for short distance transportation occasions. It mainly consists of the collection section, suction section, and the discharge section.

Compared to the common suction box, the shut-off suction box has an additional shut-off section. With shut-off function, it can clean up residual materials in the pipeline that can reduce material wastes and make it convenient for manual cleaning. Even for material replacing and conveying, it also can avoid quality problems such as material mixed due to poor cleaning, which mainly consists of the collection section, shut-off section, suction section, and the discharge section. When the suction part and collection part is collected, the materials in the collection part can be transported with the suction blower. Otherwise, it’s impossible to transport.

Selection

Usually, we will select the suction box based on actual demands. If it is a relative far distance, we will select the shut-off suction box; If there’re several injection moulding machines, it can select the multiple-pipe suction box to transport materials to two or more feed ports of the IMMs. In the food, medical, or optical occasions, it can customize the materials of the suction box contacted surface or meet other requirements.