ST1 محور مفرد مدفوع بمحرك مؤازر تحكم آلي -

الكاتالوج الاليكتروني

مقدمة

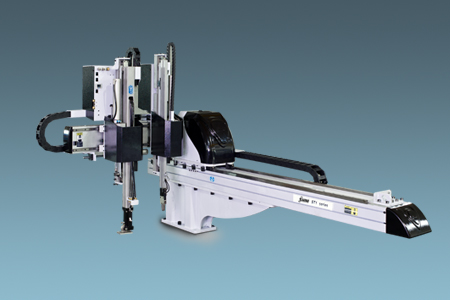

ST1 تم تصميم سلسلة روبوت لإزالة سريعة ودقيقة من ذرب و منتجات ماكينة حقن صب ، والمكان المطلوب منهم فيمواقع . القياسية ومتداخلة يتم اختيارها وفقاتطبيق لوحين قالب،و ثلاثة الواح قالب أو نظام عداء الساخنالتراص الدالة يوفر نقطتان توقف في محور X و Y، والعديد من نقاط التوقفZ. في محور T مناسبة لماكينة حقن صب تحت قوة الملقاط 850

-

ملامح

-

Appearance

Designed with elegant appearance; Aluminium profiles are largely used to provide compact and streamlined appearance.

-

Precision

Traverse movement is driven by heavy duty servo motor with cooperation of precise linear guide rails and high power V belts; Fast, silent, and precise. Wrist mechanism employs pneumatic driven rack and pinion system, which accomplishes smooth, stable and precise flipping motion. Vertical arm(s) with telescopic design efficiently minimizes the cycle time and height of the robot.

-

Safety

High efficient shock absorbers allow fast and precise pneumatic driven motion. Drop proof locking mechanism prevents accidences due to malfunction of pneumatic source. Position limit sensors and blocks effectively prevent mechanical and electrical malfunctions. Control board is designed to CE EMC test with short circuit and noise proof functions.

-

Convenience

Vertical and kick displacements can be adjusted simply by changing the position limit blocks in easy directions. Control board fixtures are designed with flyer structure which provides benefit to maintenance. Cable drag chains help with cable management and ease for maintenance.

-

Standardization

All pneumatic accessories, electric accessories, and communication Protocols meet the global standards. Interface between injection molding machine and robot is designed to EUROMAP 12, EUROMAP 67 and SPI.

-

Intelligence

User friendly control system and graphical user interface automatically monitor and display error messages with addition of memorizing last 50 errors messages. Flexible and dialogic programming scheme offer 8 standard programs and 80 customized programs.

-

User Friendly

Plug and use industrial connectors achieve simple installation and uninstallation. Servo driven axis provides the possibility of multi points for positioning products and sprues. Multi languages displays and spared communication connections with surrounds machines offer more flexibilities to global customers.